A few weeks ago, Bill and I tried to change the oil on the M3, only to find that it couldn’t drive up the plastic ramps without ripping the front bumper off. The front jack point is also too far under the engine to reach with the floor jacks we have, so it was going to be very annoying to get under the car.

Bill spent some time thinking about it, and thought we could make a pair of lower profile ramps using some 2x10 boards. We hit the HD and talked it through while there and settled on geting some 2x6’s instead, since the extra width didn’t seem terribly important, and wound up with a design that was basically just 2 2x6’s with a couple of angles cut in them to make it easier to drive the tire over the edges. We screwed the whole thing together with some deck screws, drove the car up it, and did some other work on the car, but there were still some notable issues:

- The upper platform the tires rested on was a little short, so the car rolled back a bit when we jacked up the rear of the car

- the upper platform had a small stop block to prevent the car from driving off the end of the ramp, but those broke pretty quickly since they were just screwed through the face and held in with a couple of screws

- the total lift was only a few inches (3” I supposse, since it was two pieces of dimensional lumber), which meant we STILL had to get a jack under both sides and use jack stands

So overall that worked for the work bill needed to do right then (it got the car high up enough that we could get the jack under both ends to get jack stands in there), but it was a pretty big pain in the ass and had some moments that were really annoying.

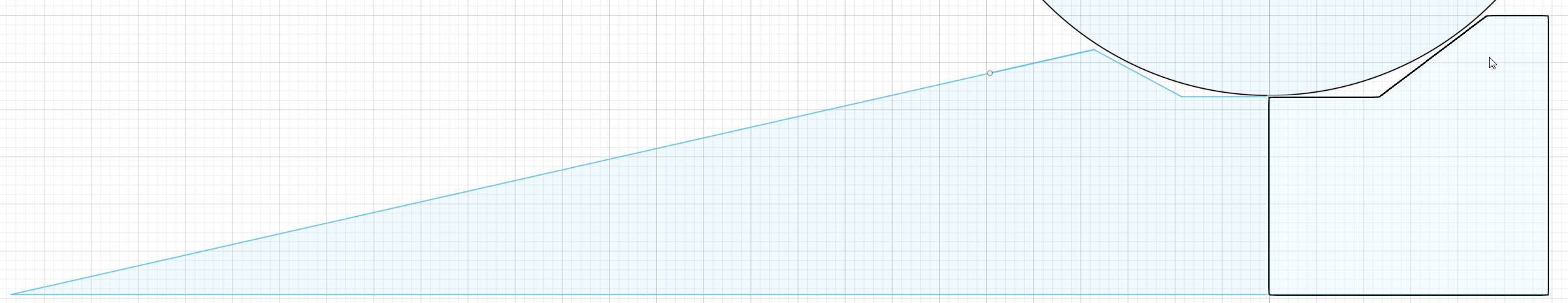

I spent a little while yesterday looking at some alternatives and taking measurements with Bill, and I’ve come up with the start of a design that’s a little better, at least. I need to figure out how to use Fusion 360 better in order to lay out what I want to do with it, and probably do some loading measurements too